A Simple Retort

Threaded end of

¼ inch pipe

4 – 6 inch dia. pipe

Practical Action

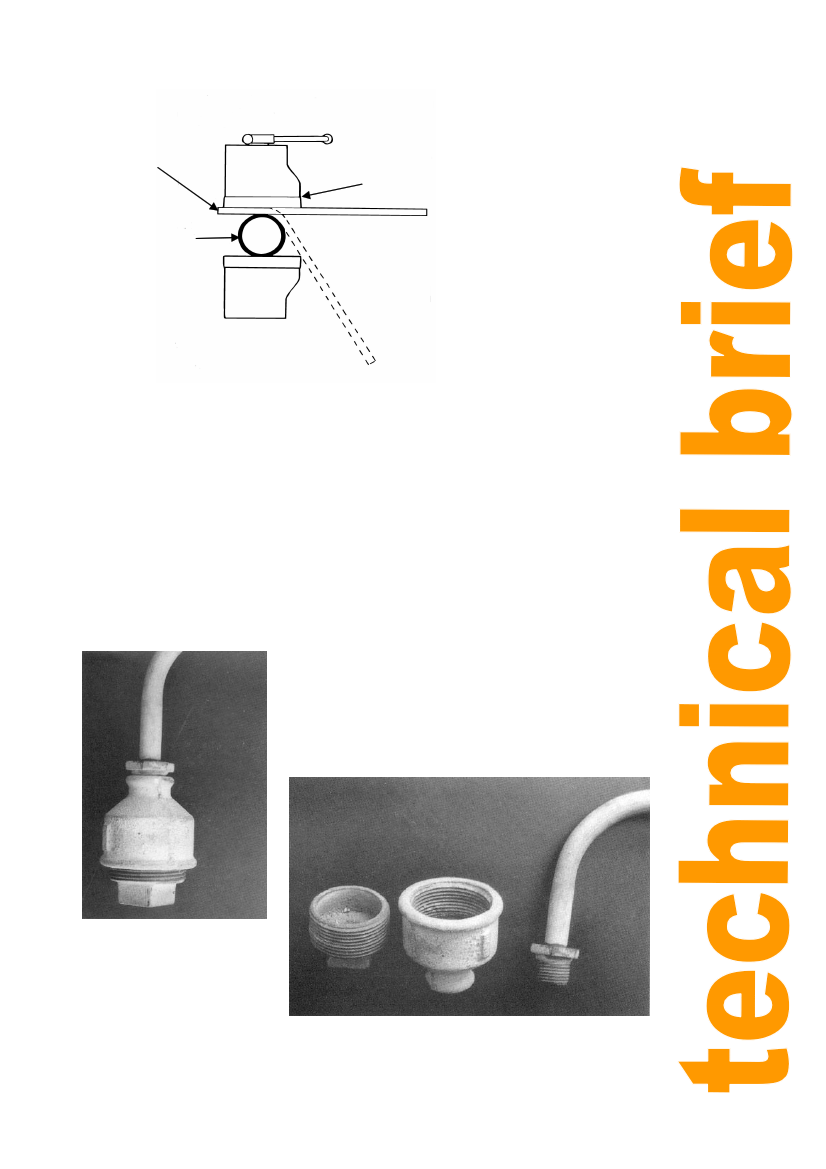

Clamp or vice

Figure 3: Pipe bending using a clamp or vice

Preparation

- Bend the pipe 4 inches from the threaded end into a smooth curve, with an angle of

about 60-70 degrees. If possible, use a pipe bending machine to have a smooth curve.

Alternatively, clamp the ¼-inch diameter pipe (2a) to a larger diameter pipe (4 to 6-inch)

and then manually bend it around the bigger pipe (Figure 3).

- Heat the pipe and fittings until red hot, before assembly, to burn off the zinc coating

(zinc reacts with mercury).

- Allow the retort to cool, then wash it.

Figure 4: Components of the assembled mercury retort

Figure 5: Separate components of the mercury retort

3